Featured Services

Mudjacking / Slabjacking

Mudjacking or Slabjacking settled concrete slabs, reinstating them to original elevations. Specializing in Sidewalks, Patios, Driveways, Pool Decks, Garage Floors, Steps, Basement Floors, Factory & Warehouse Floors, Ramps, Void Filling & Stabilization.

Compaction Grouting

Injection pipes allow grout below footings or piles to raise foundations and solidify poor ground conditions. This is a recognized structural engineering process.

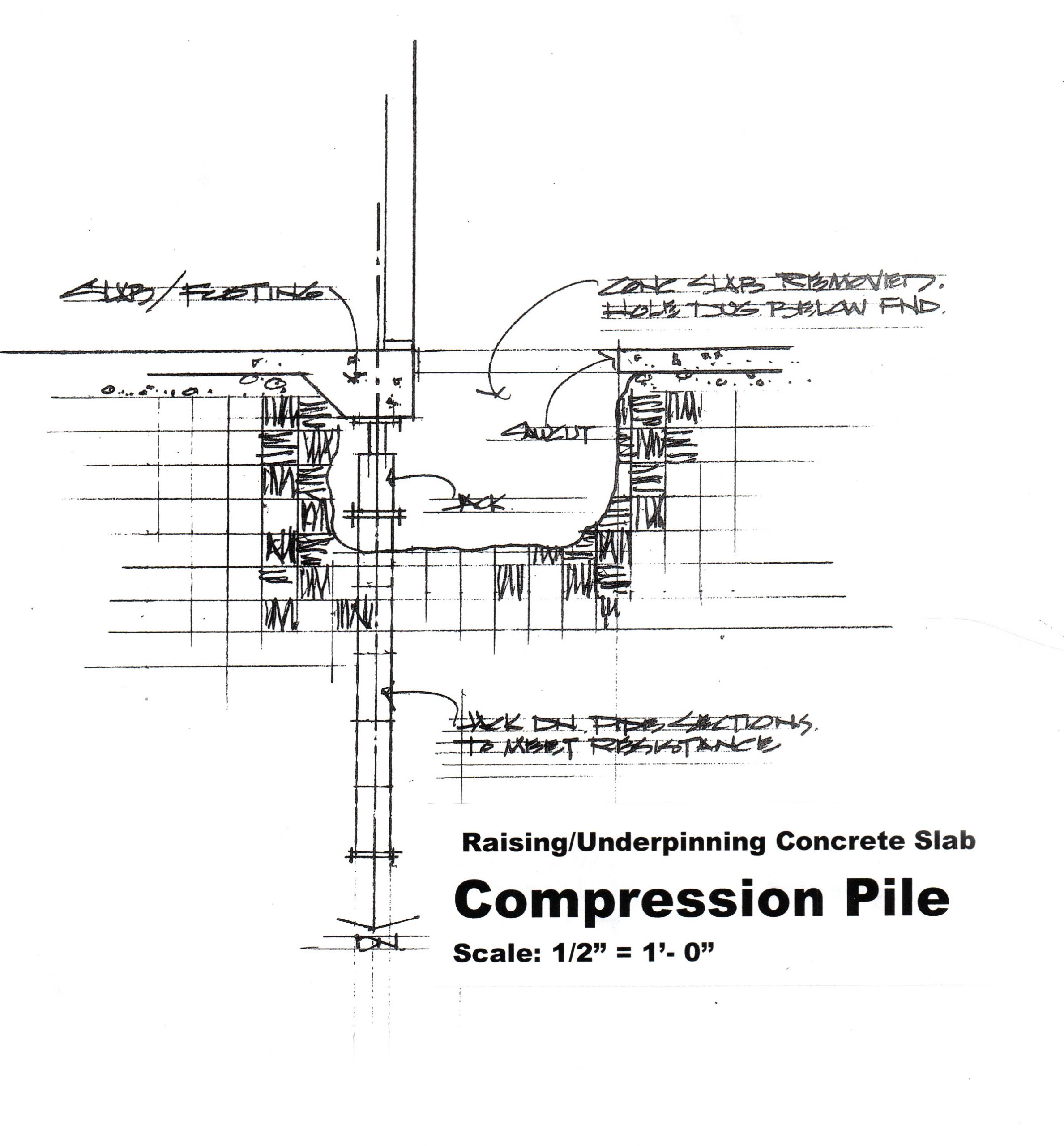

Compression Pile Underpinning System

Compression Piling is used to raise and underpin foundations that have settled. Steel casings are jacked into the ground until sufficient resistance is met. The foundation is then raised, and casings are filled with concrete.

Liquid Backfill

Liquid Backfill is a clay based, water resistant material that can be pumped to improve foundation grading, basement floor heaving and fill voids.

It’s also great for refilling new excavations with stable soil material.

Liquid Topsoil

Imagine improving the grade around your foundation without shoveling, tampers, wheelbarrows or delivery. Liquid topsoil is applied right where you need it, then compacts quickly.

Clay Spray

You have an excavation wall that has either collapsed or is precariously on the verge of collapse due to desiccation or washout. What do you do?