Featured Services

SERVICE:

Liquid Backfill

Impervious Grading Fill Application

Associated Processes: Mudjacking, Slabjacking, Slab Raising, Settled Concrete, Sunken Concrete, Concrete Raising, Cavity Fill, Washout Fill, Void Fill, Slope Stabilization, Concrete Restoration, Raising Foundations, Settled Foundations, Foundation Leveling, Excavation Contractors, Foundation Contractors, Grading Contractors, BackFill Contractors, Liquid Backfill Contractors, Home Builders, Consultants, Screw Piles, Compression Piles, Foundation Underpinning, Foam Jacking, Foam Raising, Foam Leveling, Foam Fill

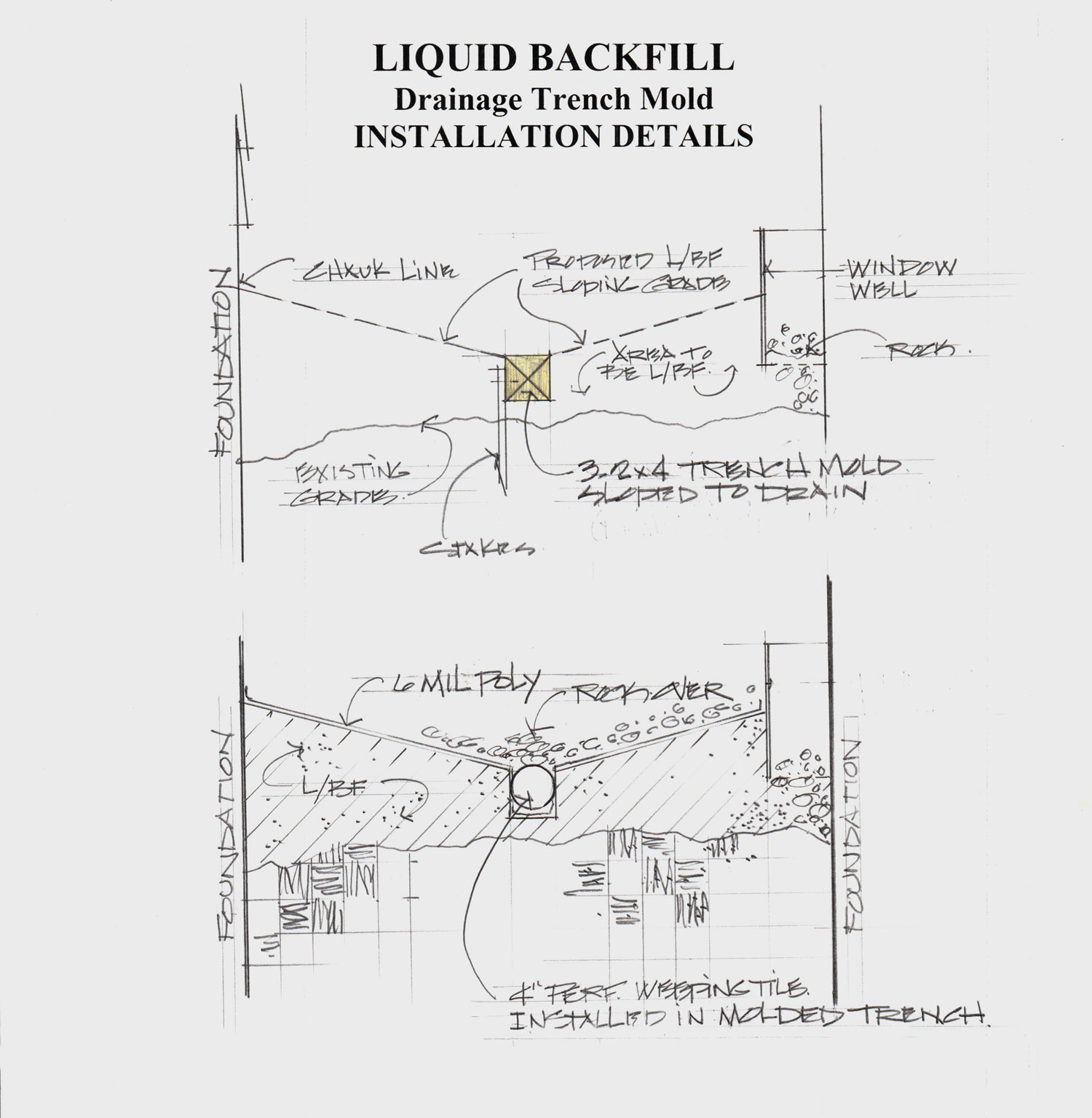

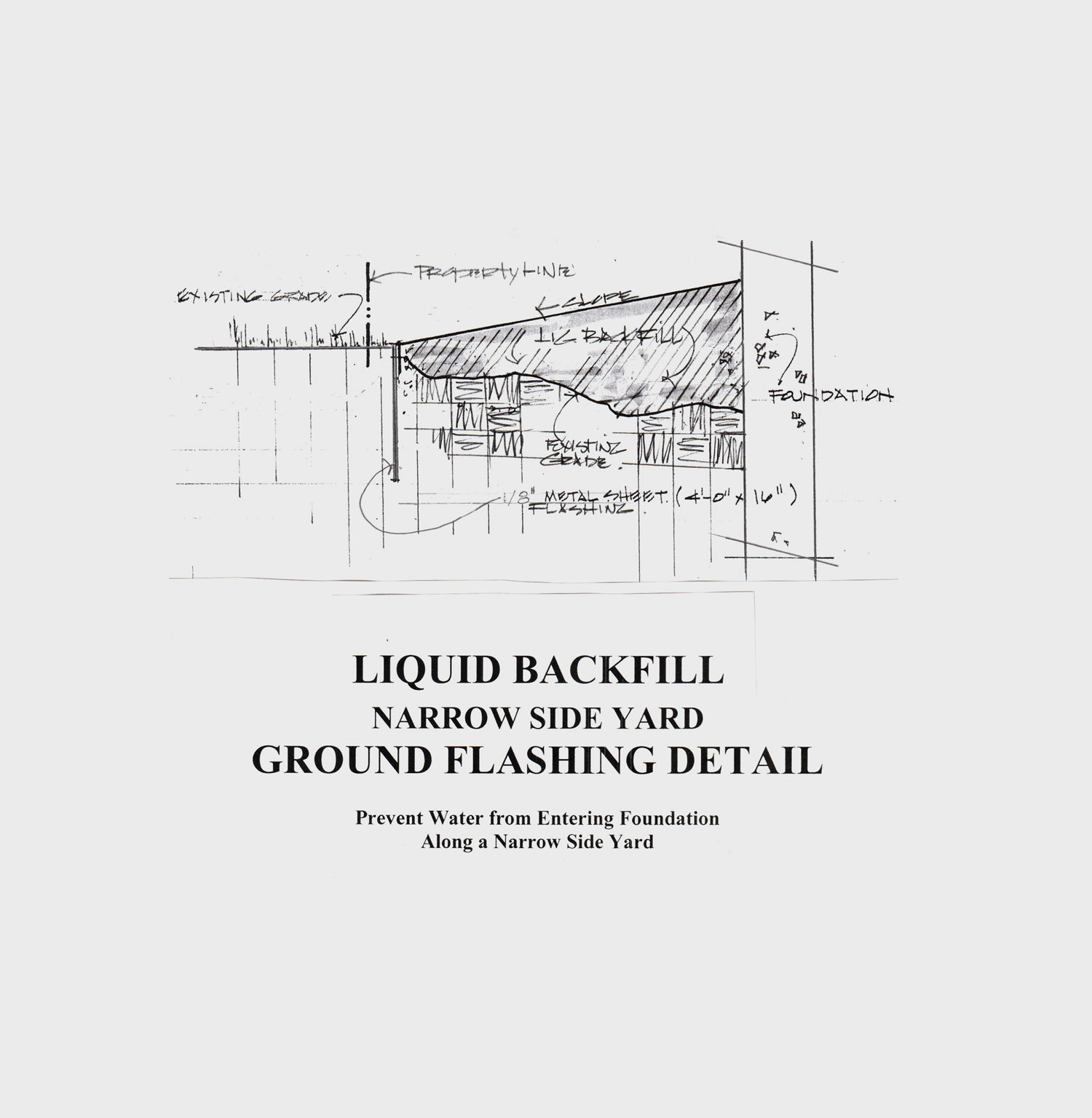

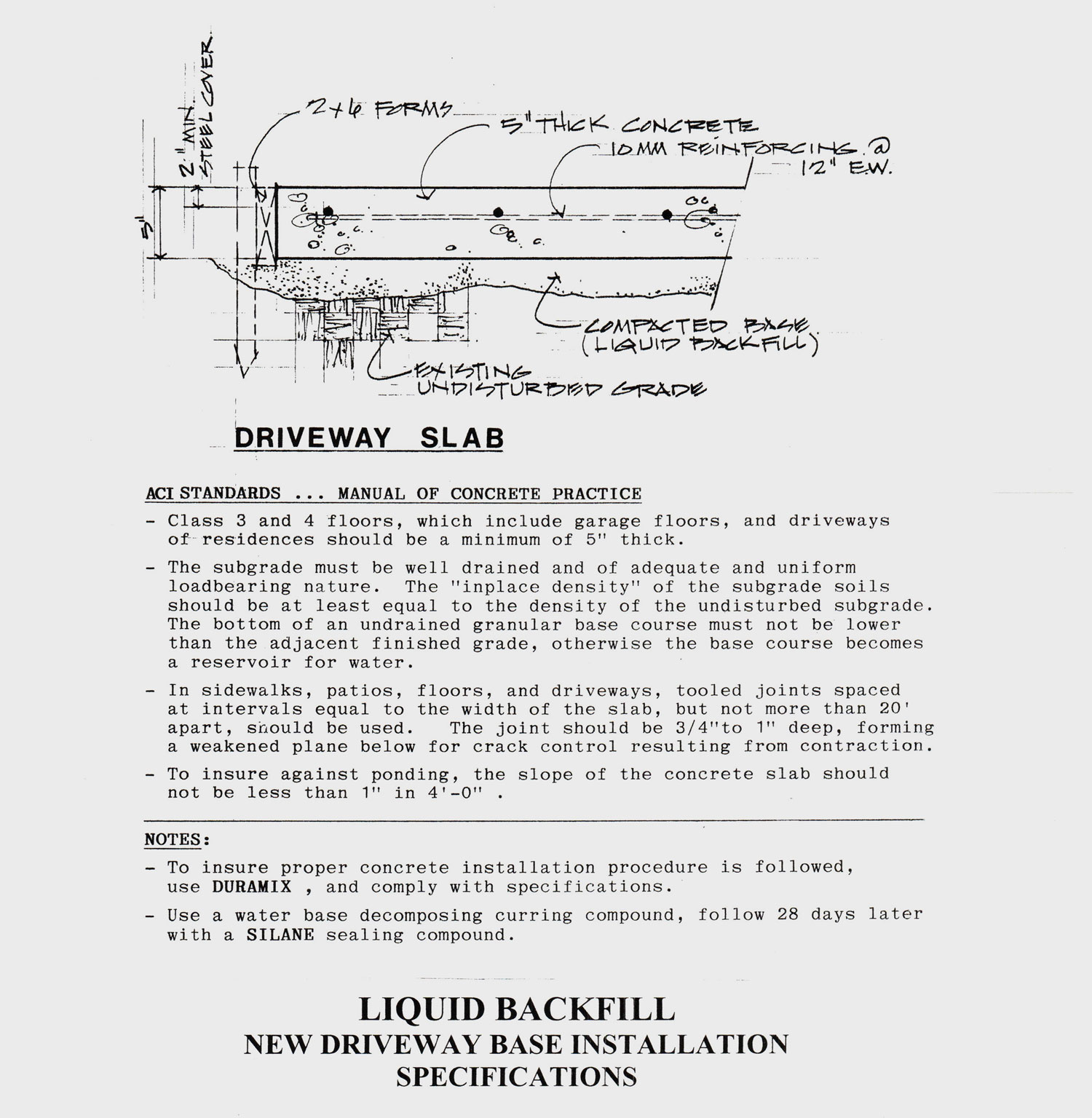

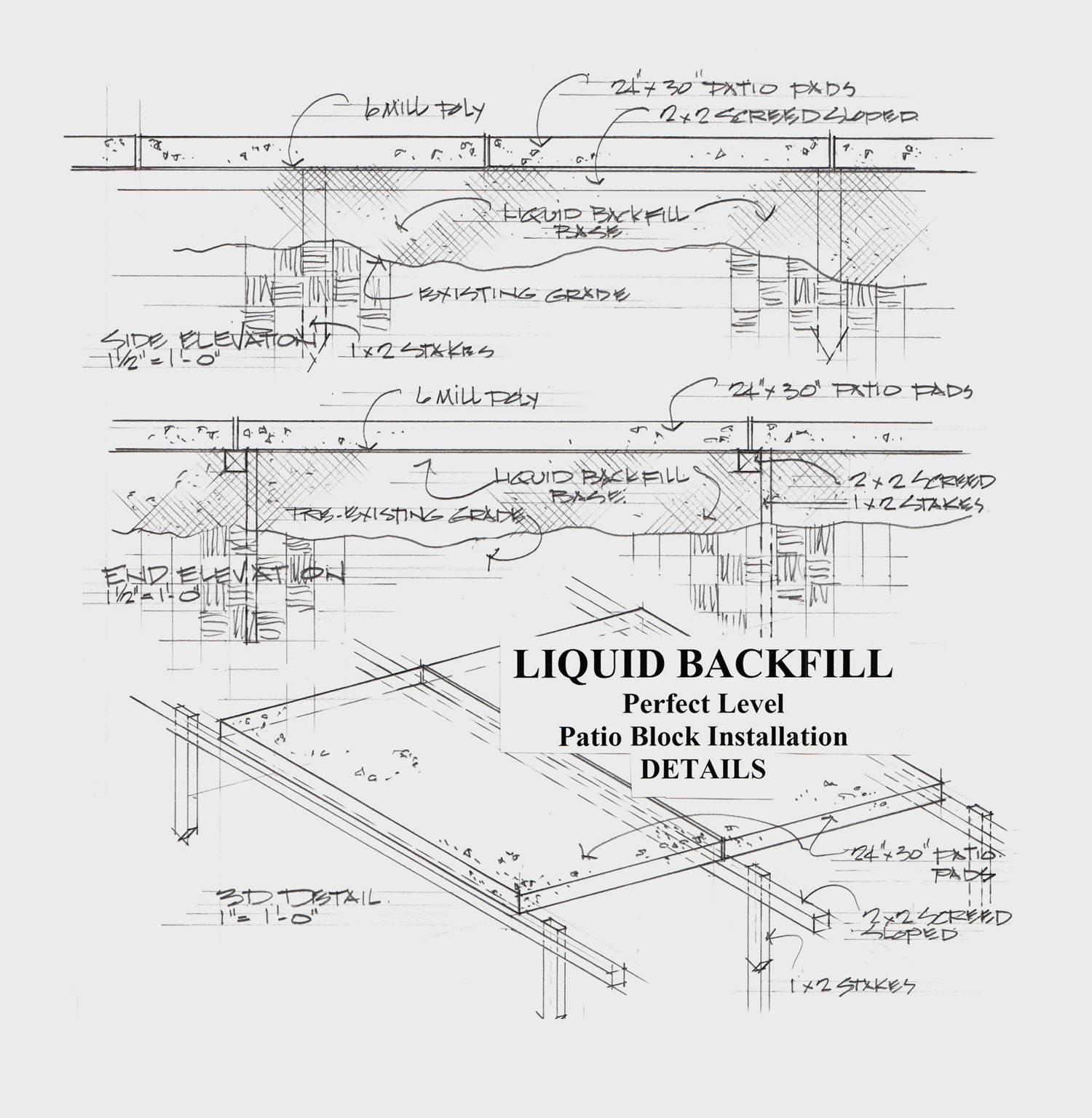

Liquid backfill is a pumpable, water-impervious clay-based material that can improve landscape grading around foundations and fill voids and cavities. It can even be used to backfill new foundations, preventing future grade settlement and water problems.

Liquid backfill can be used for shifting and cracking foundations, settled patios, driveways and sidewalks, and heaving basement floors.

Everyone strives to create low maintenance, long-lasting structures that don’t require expensive future repairs.

The proper backfilling of foundations is essential to ensure their durability and sustainability. Neglecting backfilling standards results in shifting foundations, water damage, and landscape damage. Most foundation problems can be attributed to the direct or indirect impacts of backfill settling.

Many people place too much confidence in weeping tile to protect their foundation. Poorly installed weeping tile can actually create more problems than it solves, creating low spots that can trap water and undermine a foundation.

- Expansive clay like Regina’s can cause foundations to settle in three ways.

- The weight of the foundation causes it to sink in water softened soil. Think of your boot in heavy mud.

- Flash rains and floods can remove material from under a footing.

- Tree roots grow in search of moisture-rich weeping tiles. This results in shrinkage of the bearing soil.

It is very important that the moisture condition at the depth of footings is maintained at a consistent moisture level, similar to the original moisture condition at the time of excavation. Complying with this simple rule will ensure a stable ground and foundation condition.

As industry experts, we do not recommend topsoil be used for grading and backfilling for several reasons:

- Organic material within topsoil decomposes, resulting in settlement.

- Topsoil doesn’t compact well.

- Topsoil does not shed water, instead absorbs it until saturated.

Associated Processes: Mudjacking, Slabjacking, Slab Raising, Settled Concrete, Sunken Concrete, Concrete Raising, Cavity Fill, Washout Fill, Void Fill, Slope Stabilization, Concrete Restoration, Raising Foundations, Settled Foundations, Foundation Leveling, Excavation Contractors, Foundation Contractors, Grading Contractors, BackFill Contractors, Liquid Backfill Contractors, Home Builders, Consultants, Screw Piles, Compression Piles, Foundation Underpinning, Foam Jacking, Foam Raising, Foam Leveling, Foam Fill

Liquid Backfill Grade Control to Prevent Water Seepage

Backyard Foundation Grading with Liquid Backfill Clay-Base

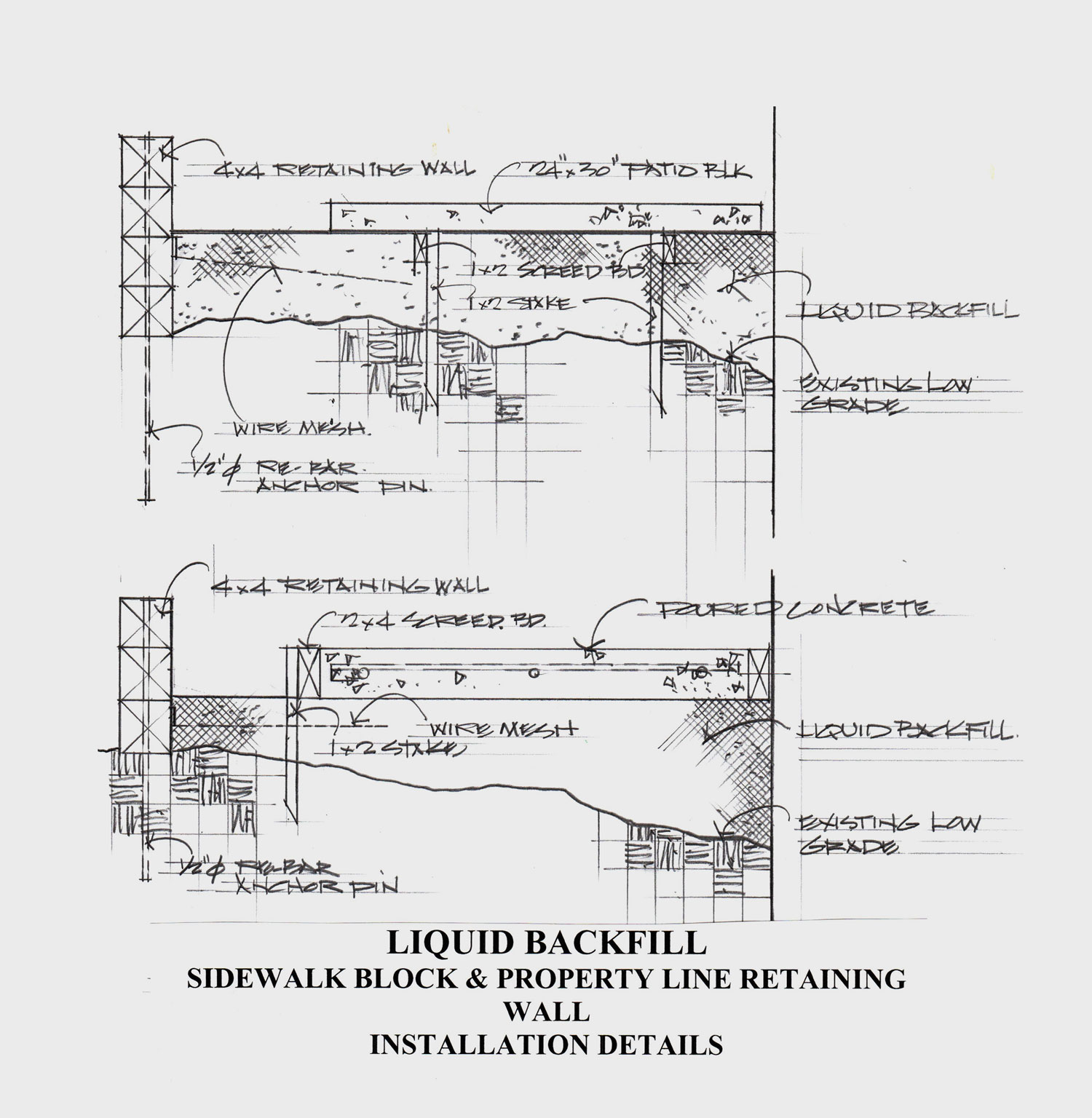

Installation of Sidewalk Blocks on Liquid Backfill

Liquid Backfill of New Foundation Excavations

Component Concrete Pad Installation

Liquid Backfill Base for Interlocking Paving Stones

SERVICE:

Liquid Topsoil

Associated Processes: Mudjacking, Slabjacking, Slab Raising, Settled Concrete, Sunken Concrete, Concrete Raising, Cavity Fill, Washout Fill, Void Fill, Slope Stabilization, Raising Foundations, Settled Foundations, Foundation Leveling, Excavation Contractors, Foundation Contractors, Grading Contractors, BackFill Contractors, Liquid Backfill Contractors, Home Builders, Consultants, Screw Piles, Compression Piles, Foundation Underpinning, Foam Jacking, Foam Raising, Foam Leveling, Foam Fill

Liquid Topsoil is another landscaping innovation from Gunner LiftCrete that eliminates the need for shoveling, disruptions, messes, wheelbarrowing, grade leveling, roller packing, and avoids labour intensive contour development, and above all…is quick and easy to create.

The application makes the installation of a water sprinkler system simple by eliminating the need for trenching and having to bury the water lines placed in the trenches. Planters, retaining walls, can be constructed, ie 4×4 cedar, or concrete blocks, ready to be filled with the Liquid Topsoil, and any existing shrubs can simply be poured around, at the base, and left undamaged.

It is not important for the basic ground area to be leveled, prior to the installation of Liquid Topsoil. The elevation of the finish topsoil grade will be leveled or contoured, as defined by the top of stakes pre-placed into the ground in accordance with a landscape design.

The water sprinkler hose system is simply laid out on top of the existing ground, with the sprinkler locations tied to a piece of rebar that will mark the location once the Liquid Topsoil has been installed. Stiff “U” shaped tie-down wires are pushed into the ground saddling the sprinkler hose to prevent the hose from floating when covered with liquefied topsoil. These tie-downs wires are left buried within the Liquid Topsoil.

The fill process involves the Company’s mobile batch plants loaded with 12 cubic yards of good quality black topsoil, which the customer has selected from a local material supplier.

The batch plant mixes water into the dry topsoil to create a liquid (mud), which is augured into a pump that pumps the Liquid Topsoil through a 2-inch diameter hose to the area being filled. As the Liquid Topsoil is being discharged from the 2-inch hose, workers squeegee the thick liquid into a finish that is guided by elevation stakes, which remain buried within the Liquid Topsoil.

Within a few hours, the yard is ready for sod placement or grass seed, over a topsoil base containing a high degree of moisture content, which is very beneficial to sod growth.

The finished product will comply with the landscape profile design, properly graded and contoured, a project you can be very proud of.

Liquified Top Soil Installation / Embedding Sprinkler System

Associated Processes: Mudjacking, Slabjacking, Slab Raising, Settled Concrete, Sunken Concrete, Concrete Raising, Cavity Fill, Washout Fill, Void Fill, Slope Stabilization, Raising Foundations, Settled Foundations, Foundation Leveling, Excavation Contractors, Foundation Contractors, Grading Contractors, BackFill Contractors, Liquid Backfill Contractors, Home Builders, Consultants, Screw Piles, Compression Piles, Foundation Underpinning, Foam Jacking, Foam Raising, Foam Leveling, Foam Fill

SERVICE:

Clay Spray

Associated Processes: Mudjacking, Slabjacking, Slab Raising, Settled Concrete, Sunken Concrete, Concrete Raising, Cavity Fill, Washout Fill, Void Fill, Slope Stabilization, Raising Foundations, Settled Foundations, Foundation Leveling, Excavation Contractors, Foundation Contractors, Grading Contractors, BackFill Contractors, Liquid Backfill Contractors, Home Builders, Consultants, Screw Piles, Compression Piles, Foundation Underpinning, Foam Jacking, Foam Raising, Foam Leveling, Foam Fill

You have an excavation wall that has either collapsed or is precariously on the verge of collapse due to desiccation or washout. What do you do?

Clay Spray is a Gunner LiftCrete innovation that is an economical and quick solution to your collapsing dilemma…Clay Spray is a clay/sand mixture combined with minimal cement, which is pneumatically sprayed against the excavation wall to effectively stabilize and arrest further collapse and coat the excavation wall preventing the further loss of moisture.

The process is similar to a Shotcrete application, with only a clay/sand material blend (not concrete) that is mixed by a mobile batch plant truck, augured into the hopper of a concrete line pump, that then pumps the material to the discharge end of a 2-inch diameter hose where an airline is connected to a nozzle.

As the material is pumped through the nozzle, compressed air blows the material out in a shotgun blast pattern that impacts as it molds, and adheres to the existing excavation wall. If additional membrane support is deemed necessary, a standard redi-mix polypropylene fiber can be added into the mix.

The material is low slump (2 inches) and with the minimal cement content, it sets up quickly into a monolithic layer that will provide the support necessary to prevent collapse and provide safety within the area.

It is clear the economics of the process is derived from the low-cost materials used in the application. This application can be used to build up an irregular sloping surface prior to pouring a concrete slab, such as retaining walls.

The Company has also reinstated washout lakeside property lines, which may require a substantial thickness of the claylike material to bring the property line back to its original profile and alignment.

The application of Clay Spray by Gunner LiftCrete is another innovative proprietary application that is open to the imagination, regarding the scope of its uses as a vertical type stabilizer and filler.

Please call, we are always open and interested in talking with you regarding any application ideas you may have.

Associated Processes: Mudjacking, Slabjacking, Slab Raising, Settled Concrete, Sunken Concrete, Concrete Raising, Cavity Fill, Washout Fill, Void Fill, Slope Stabilization, Raising Foundations, Settled Foundations, Foundation Leveling, Excavation Contractors, Foundation Contractors, Grading Contractors, BackFill Contractors, Liquid Backfill Contractors, Home Builders, Consultants, Screw Piles, Compression Piles, Foundation Underpinning, Foam Jacking, Foam Raising, Foam Leveling, Foam Fill