Mudjacking/Slabjacking

SERVICE:

Mudjacking / Slabjacking

Associated Processes: Mudjacking, Slabjacking, Slab Raising, Settled Concrete, Sunken Concrete, Concrete Pumping, Concrete Raising, Cavity Fill, Washout Fill, Void Fill, Grouting Contractors, Concrete Repair, Concrete Leveling, Concrete Alignment, Misaligned Concrete, Heaved, Concrete, Concrete Restoration, Pressure Grouting, Compaction Grouting, Raising Foundations, Settled Foundations, Foundation Leveling, Consultants, Screw Piles, Compression Piles, Foundation Underpinning, Foam Jacking, Foam Raising, Foam Leveling, Foam Fill

Hazardous Foam Jacking…

Respirators Required

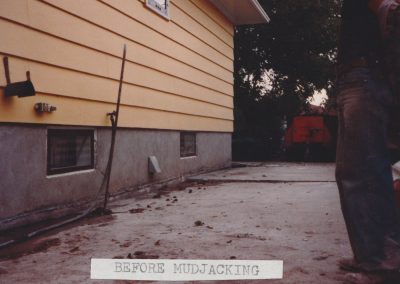

MudJacking is also known as SlabJacking. The process is the same – a stabilizing low slump grout material is sequentially pumped underneath a concrete

slab through 1.5” holes triangularly patterned, and spaced 3 to 5 feet apart using a pneumatic or electric drill. These access holes are located in the area of slab settlement and where cavities below the slab are required to be filled.

Our experienced crew will develop the optimal access-hole layout unique to your project. The injection generally starts at the point of greatest settlement. Lifting is carefully done at about 1/4” intervals working towards the high elevation, and repeated as many times as necessary until the slab is raised to original elevation and alignment. Secondary access-holes are drilled in key locations, generally within the central area of the slab, where a high slump/flowable grout is then pumped under the slab to ensure the entire slab is properly filled and supported. This secondary application is very important to the long-term success of the project since so many concrete slabs vary in thickness and if they are not properly supported cracks and sags will occur when heavy vehicles are driven over it.

The consistency of the grout is adjusted to best suit the project conditions. The grout material is allowed to harden to provide a stable sub-base that will never deteriorate, and will always be there as a defined layer.

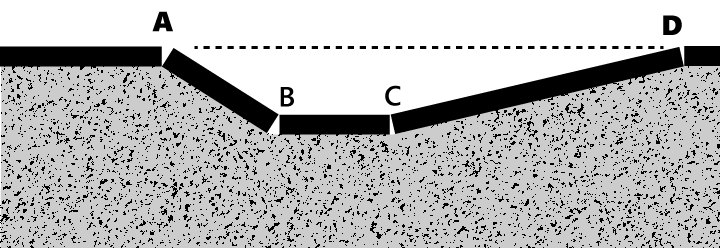

The important advantage MudJacking has over foam involves the Mudjack grout which is able to migrate into the smallest spaces, filling all voids and cavities, contrary to the quick setting time of 5 seconds, typical of all foaming products, that results in foam pillow blobs under the slab causing even more voids and cavities …a foam jacking process leaves a slab in a precariously supported condition that leads to unnecessary slab damage, and safety issues.

MudJacking material creates a solid universally supported solid base that concrete slabs require for support, this base also acts as a barrier/dam preventing water from migrating under the slab and then down into your basement.

There is nothing in the market that can beat the time-tested, simplicity and reliability, of a well-done MudJacking project.

MudJacking offers many advantages over any other methods:

-

Less costly and less disruptive than concrete replacement;

-

Less costly that foam jacking;

-

Mudjacking grout easily fills tapering cavities as well as large voids, cavities, and washouts;

-

Mudjacking grout material is easily cleaned with only water, not possible with the sticky foam products that require a hazardous solvents.

-

Can be done at any time of the day or night;

-

Mudjacking can be done at long distances;

-

The existing surface of the concrete is maintained;

-

The grout used solidifies to effectively stabilize concrete slabs over a universal compact base of support;

-

Mudjacking blocks water from saturating beneath the slab, thereby minimizing and often eliminating freeze/thaw shifting, heaving, and crack damage;

-

Water run-off can be redirected to avoid leaky wet and shifting basements;

-

Properly executed MudJacking does not create new cracks, but some old crack types (ie: sag related cracks) may open and appear due to the physics of levelling;

-

Mudjacking does not exert pressure on an adjacent foundation wall, simply because Mudjacking is not a confined hydraulic system process, there are any number of exit conditions, such as: the adjacent ground, the adjacent access holes with any number of cracks and joints that allow the grout material to easily escape, while the nozzle used is a loose fit in the access holes. Keep in mind that MudJacking and the foundation raising process Compaction Grouting are two completely different procedures, so it is important not to get the two confused.

- MudJacking material is proportionally heavier than foam. However, being a lighter material is of no advantage, when the foam pillow blobs create point- loading conditions required to carry a heavier concrete slab load on a smaller area of support, which actually jeopardizes the integrity of the concrete slab being propped up on a scattering of foam blobs. So, don’t let the false and misleading foam promotion fool you;

- MudJacking projects can easily be re-MudJacked indefinitely, whereas re-foam touch-ups leave behind even greater voids and cavities under the slab. Foam jacking cannot properly honour touch-up warrantees without creating an even bigger problem;

The foam jacking process is new to the slab raising market, whereas Mudjacking has a proven legacy record tracing back to the early 1930’s.

Foam uses hazardous and toxic chemicals that must be properly handled and removed should you decide to ever replace your concrete slab; this is not the case with MudJacking materials. See the attached links on this page relative to foam jacking problems;

One must seriously question the honesty of the foam jacking advertisements when they have to show fake foam filling under a concrete slab. The foam jacking advertisements further show the actual foam pillows that are

surrounded by cavities, typical of all foam installations; The foam jacking process using hazardous foam chemicals…is another source of toxicity contaminating the environment.

Gunner-LiftCrete provides a two-year residential “touch-up” warrantee, which only applies to homes older than 10 years, due to the poor backfilling practice typical to new foundations constructed within the community.